Reverse Engineering

Recreate, refine, and modernize products with accuracy and precision

At Mech Flow Designs, our Reverse Engineering services focus on transforming existing components into precise digital models. Using advanced scanning, measurement, and CAD reconstruction, we deliver general reverse engineering for mechanical parts and assemblies, as well as specialized solutions for medical devices and electronics. These services enable accurate replacements, design improvements, and modernization while ensuring reliability, performance, and compliance with industry standards.

-

Reverse Engineering (General) Recreate mechanical components and assemblies with precise digital models, ready for redesign or reproduction.

-

Specialized Reverse Engineering (Medical Devices & Electronics) Accurate reconstruction of medical and electronic products for improved performance, documentation, and compliance.

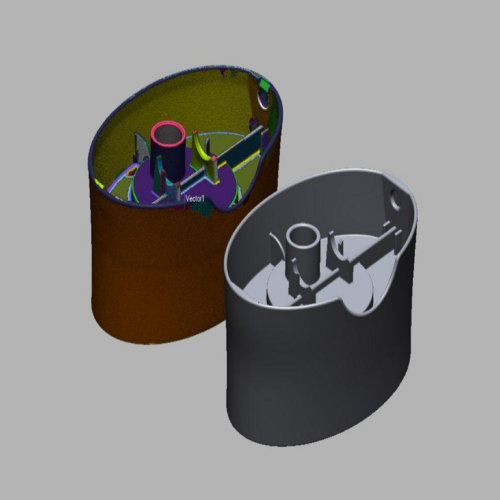

Our Work in Action

Exhaust Flange

A car exhaust flange was reverse engineered from STL data using Geomagic Design X, achieving ± 0.1 mm accuracy. Key features such as bolt holes, sealing face, and fillets were modeled for strength and precision. The final CAD was exported in STEP/IGES for manufacturing with SS304, ensuring reliable fitment and performance at temperatures up to 600°C.

Alloy Rim

A damaged alloy rim was reverse engineered from 3D scan data and rebuilt in SolidWorks with ±0.15 mm accuracy. Key specs — 16” diameter, 6.5” width, and 5-lug PCD 114.3 mm — were parametrically defined. Spokes and hub regions were remodeled to retain style and strength, while mounting surfaces achieved ±0.05 mm tolerances. Final CAD (STEP/IGES) supports casting, CNC machining, and stress analysis, enabling precise reproduction or design upgrades.

Gear Component

A broken gear was reconstructed from STL scan data in Geomagic Design X with ±0.05 mm accuracy. Complex tooth geometry, pitch circle (120 mm), module (3 mm), and 20 teeth were restored, along with keyway tolerances for manufacturability. The final STEP model enabled CNC machining and reliable replacement where original drawings were unavailable.

Quick Links

Get the updated

iPad Templates

You can also reduce the extra loading time in your WordPress websites. Leverage the best addons pack for the Elementor page builder.

- Sync to Cloud

- Create Your Own Palylist

- Share Instantly